The ‘Shubham’ quality

‘Shubham’ committed to manufacture ‘best’ in terms of quality. It is equipped with world-class R&D unit, physical and chemical laboratories. It takes pride in possessing a technologically advanced captive power plant. The whole set up follows a ‘M2M’ structure (Mine to Market). The entire chain is owned and hence closely monitored by trained engineers, under supervision of top management itself. That is why it is capable of maintaining a strict quality control across the 7 stages. The Shubham Thermex TMT Bar has the best composition as per Bureau of Indian Standards

.

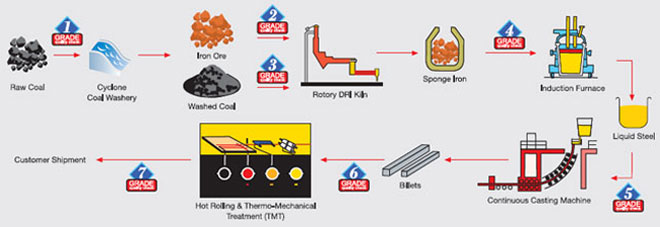

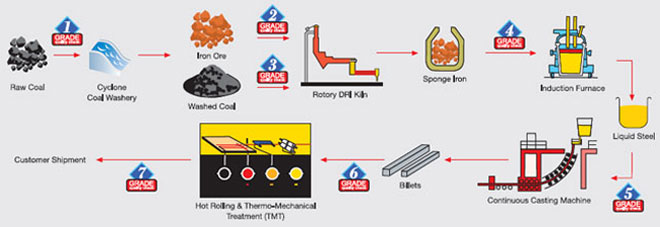

7 Grade Quality Check Mechanism.

In the First QC Stage…..Coal and Iron Ore, the 2 major raw materials, pass through vigorous tests in state of the art laboratory to ensure the best input of the base materials.

The coal is then fed to the fully automatic Coal Washery Unit where the impurities of coal is removed using the sophisticated machineries sourced from across the world like UK, Germany, South Africa and so on. The second stage of Quality check is done to ensure consistent quality of Washed Coal.

Washed coal is then processed with Iron ore and dolomite and to produce DRI… The third stage of Quality check ensures the right quality and size of raw material is fed.

The D.R.I. Unit is fully automated and constant monitoring of various parameters by highly qualified and skilled operators helps to attain the best industry.. The fourth stage of Quality Check approved the DRI quality.

Kohinoor has its own 17 MW Captive Power Plant which provide power to all the other units.The DRI produced is taken into its own Steel Melting Shop (SMS ).. The hot metal samples are drawn and taken to the fifth stage of Quality check before it is approved to be poured.

The hot liquid metal is poured into Kohinoor’s own CCM unit and converted into ISI quality approved billets. The sixth stage of Quality Check approves it for further processing after using sophisticated machines like Imported Spectrometer, Crack Analyzers, Carbon Apparatus, etc.

The ISI- quality approved billets are taken to the Sophisticated Rolling Mill where they are heated in furnace fueled by PGP plant to get uniformly heated up to 1300°C. Then the billets are guided to the Roughing strands to enhance ductility. Subsequently it goes through Continuous roughing and Finish continuous process. This is followed by water spraying in the Thermex Quenching system and the different size (8 mm to 40 mm) TMT rods are brought to the automated cooling bed. These are then cut in lengths of 9 to 12meters and bundled in the fully Automated Bending Machines for dispatching to its customers. Shubham Reinforcement Steel Bars goes through rigorous testing process of International Standards in its Seventh and the Final Stage of quality Check. Here the best machines like Universal Testing Machine, Bend Testing Machine, etc. are used to ensure the best product is made.

For Kohinoor’s Shubham Fe 500 D Re-inforcement TMT Bars... Stronger, Safer and Superior… Quality is the Ultimate Mantra. |